One of the most nonconventional automakers is taking a nonconventional approach to building desperately needed medical equipment to battle the coronavirus pandemic.

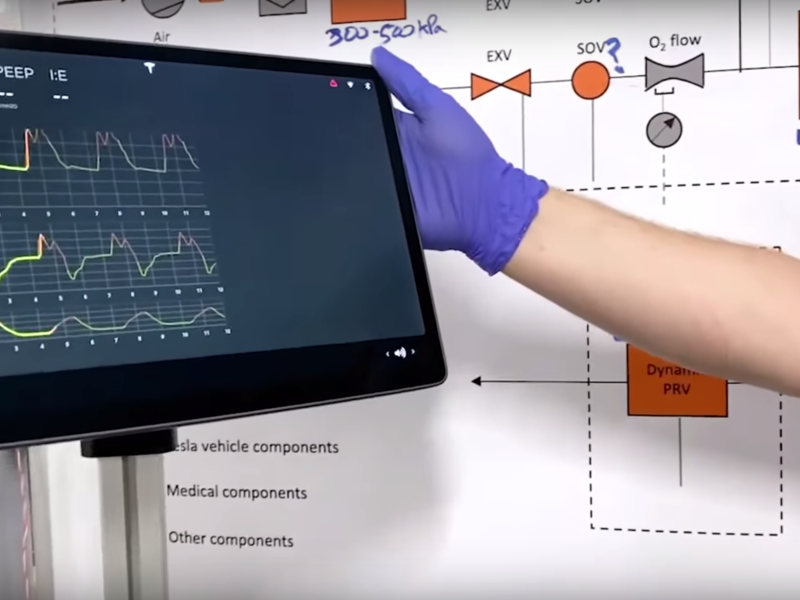

Tesla posted a video Sunday describing how engineers were working on a prototype ventilator using a number of vehicle parts, including the display screen and infotainment computer from the Model 3 sedan. The computer is used to control sensors on an airflow manifold, and the display screen is used to monitor patient breathing patterns.

The design utilizes a suspension air tank as an oxygen mixing chamber, as well as a number of other sensors, compressors and tubes.

An unidentified employee said on the video that Tesla was attempting its own design instead of traditional methods to avoid putting additional strain on medical equipment suppliers. It was unclear when the prototype would be complete, whether the automaker intended to manufacture the device in bulk, or if the designs could pass rigorous medical quality standards.

“There’s still a lot of work to do, but we’re giving it our best effort to make sure we can help some people out there,” the employee said.

Tesla CEO Elon Musk, after initially downplaying worry about the virus, said late last month that the company’s New York gigafactory would open “as soon as humanly possible” to build ventilators and that Tesla would “do whatever is needed to help in these difficult times.” In the meantime, the automaker has donated BiPAP breathing machines for use as noninvasive ventilators to a number of states, including Michigan.

Musk’s SpaceX also is supplying valves for ventilators produced by Medtronic.

A number of automakers in recent weeks have pivoted from building vehicles to building ventilators, respirators and personal protective equipment to help medical professionals and those suffering from COVID-19.

General Motors is working with Ventec to build ventilators at its Kokomo, Ind., plant, while Ford Motor Co. is partnering with GE Healthcare to assemble 50,000 ventilators in 100 days at a components plant in Ypsilanti, Mich., starting later this month.

Both automakers are essentially contract manufacturing established ventilator designs, as opposed to designing one from scratch.

“We want to use parts we know really well, know the reliability of and we can go really fast and they’re available in volume,” Joseph Mardall, a Tesla engineering director, said on the video.