Polestar will take over part of Saab‘s former car plant in Sweden to extend its R&D operations in Europe.

The EV maker will conduct powertrain development for the Polestar 5, a Tesla Model S rival, and the Polestar 6 roadster at a 15,000-square-meter building in Trollhattan, Automotive News Europe sister publication Automobilwoche reported.

Polestar will also test powertrains, electric motors and batteries for the upcoming models at the new R&D center.

Polestar will rent the building from the city of Trollhattan, Automobilwoche said.

The site was previously used for powertrain development by Saab and then by National Electric Vehicle Sweden (NEVS).

Saab collapsed in 2011 and NEVS closed down last month.

Polestar also has R&D facilities in Gothenburg, Sweden, which is about 90 km south of Trollhattan, and in Coventry, England. In England the automaker is developing its own lightweight bonded-aluminum platform that will underpin Polestar 5 and Polestar 6.

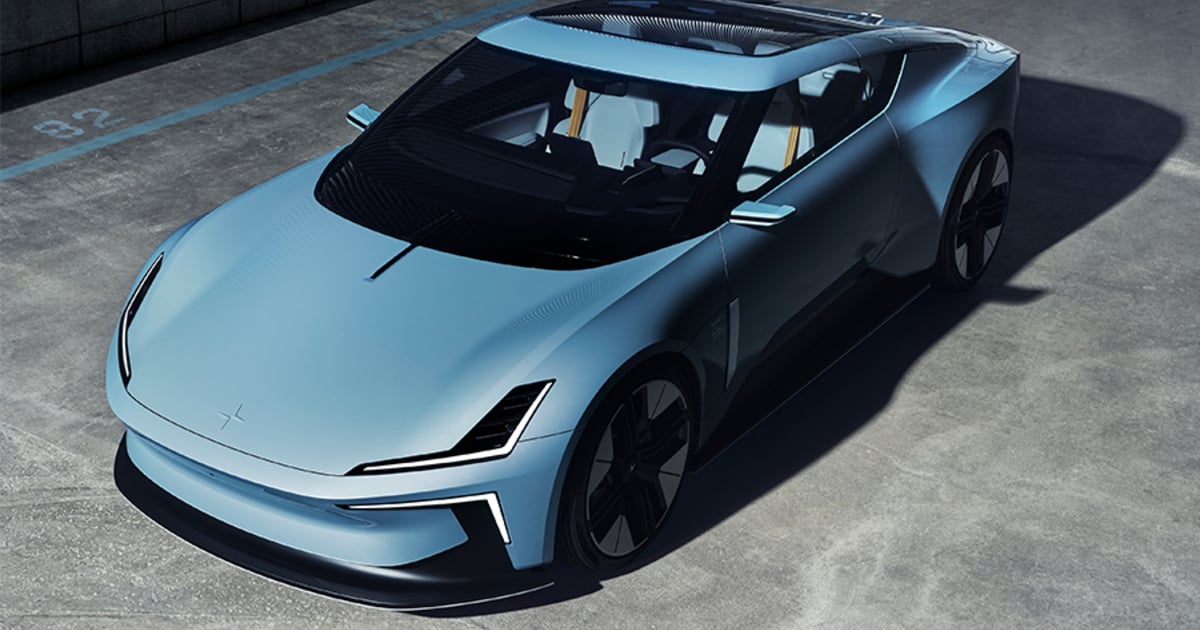

The Polestar 5, which will also compete against the Porsche Taycan, is scheduled to go into production in 2024 at a plant in Chongqing, China. The Polestar 6 hardtop convertible will also be built at the plant, likely starting in 2025. The plant is owned by Geely and operated by Polestar. Polestar’s new platform has not been named yet.

The cars will share an 800-volt electric architecture that in addition to providing nearly 900 hp of power will offer 900 newton meters of torque, 0 to 100 kph (62 mph) acceleration in 3.2 seconds, a top speed of 250 kph (155 mph) and an estimated range of more than 480 km (300 miles), the automaker said.

Production planned?

When asked whether Polestar would also use the Trollhattan site to start building cars, a spokesperson told ANE that the brand would continue to rely on its sister brands for production. Therefore, it will still need to negotiate for space in factories where the CMA, SPA2 and SEA platforms are used.

All Polestar models are built at plants owned by Volvo and Geely, which turned Polestar into a stand-alone brand in 2017 and are strategic partners in the Nasdaq-listed company.

The Polestar 2 midsize fastback is built in Luqiao, China, on the CMA platform at a factory owned by Geely and operated by Volvo.

The Polestar 3 flagship large SUV will be underpinned by SPA2 and be made at Volvo’s plants in Chengdu, China, and in the U.S. near Charleston, South Carolina.

The Polestar 4 coupe-styled SUV will be built at Geely’s factory in Hangzhou Bay, China, using the SEA underpinnings.

Polestar aims to increase global sales 60 percent this year to 80,000 units. That number is below what the automaker predicted it would achieve in materials prepared ahead of going public. The 2023 goal was 124,000.

Polestar listed on the Nasdaq exchange last June via a merger with a special-purpose acquisition company (SPAC).

Despite the adjustments, Polestar is sticking with the long-term targets of its business plan, which include global sales of 290,000 by 2025 and becoming profitable by 2024.

Michael Knauer of Automobilwoche contributed