As the electric vehicle era dawns, automakers are looking left and right for ways to make their vehicles more efficient and to streamline their manufacturing.

Because of that, much attention is given to battery performance, the lightweighting of huge components such as body frames or door panels, the development of new supply chains, and other high-profile ways companies are looking to become leaner and more efficient.

But achieving those savings comes not only through major projects but also by making ongoing changes to smaller components throughout the vehicle.

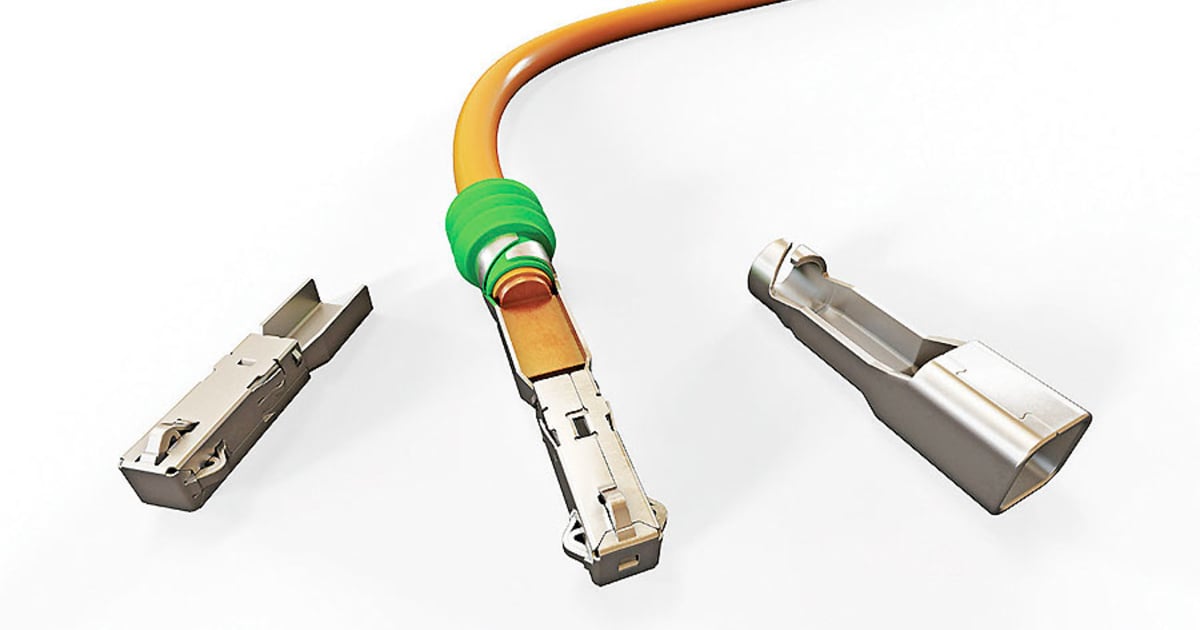

Case in point: the new power connectors that Eaton Corp. is rolling out. The power management supplier said its new high-power lockbox power connectors are easier to build, safer to use and smaller than traditional connectors, leading to better performance in both EVs and internal combustion engine vehicles.

“This is something to get twice the current for basically half the space due to the design,” said Chris Mancuso, Eaton’s general manager of power connections. “For vehicle makers, that means better packaging in the vehicle. They can charge the battery faster. And it can help make their vehicles lighter because we’re using less space.”

The connectors were developed and designed by Royal Power Solutions, an electric connectivity components company Eaton acquired for $600 million last year.

The design differs from traditional “box-and-blade” connectors, which can loosen when exposed to heat or vibration, Eaton said. When that happens, power flow in the vehicle is reduced and the possibility of corrosion increases.

Eaton’s design innovation uses an “inside-out contact system,” which includes multiple contact points and internal spring pressure to keep it secure and improve performance.

“These connectors need to be watertight,” he said. “They need to withstand all the things we drive through.”

The connectors are roughly half the size of traditional ones, and are easier and safer to install, he said. Traditional connectors need to be installed manually, often by workers wearing two sets of gloves for their protection, he said. Not only is there a safety risk for workers, but there is a risk that the systems won’t be installed properly, resulting in power flow issues.

The new design can be installed by a robot, making the manufacturing process safer and more efficient, he said.

“It’s easier on our operators, and it’s just a more ergonomically friendly solution,” Mancuso said.

“For our customers, it’s a higher quality process and there’s less risk from a warranty perspective.”

Eaton is rolling out three variants of the product to unnamed customers in North America and plans to ramp up production as EV sales rise.

The supplier will begin with light-vehicle production in North America before expanding to other regions and potentially into heavy-duty vehicles, or even non-automotive applications, Mancuso said.

“For us,” he said, “having a product that does the same job or better with less material, you’re enabling the electric vehicle revolution in a smarter way.”