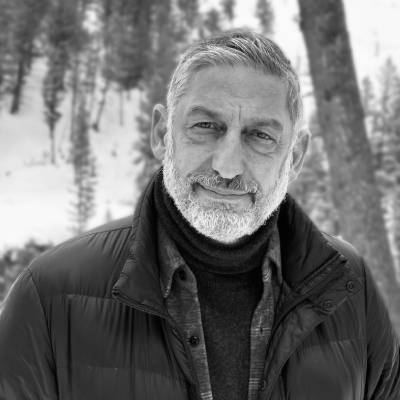

As global trade policies shift, small and medium-sized businesses (SMBs) are grappling with heightened supply chain uncertainty. Potential tariff changes under Donald Trump’s presidency could lead to rising costs and a greater emphasis on domestic sourcing. In this Q&A, Netstock CEO Ara Ohanian explores strategies like nearshoring, inventory optimization, and supplier diversification to help SMBs build resilience in an evolving trade environment.

Supply Chain 24/7: How do you foresee Donald Trump’s potential trade policies impacting SMBs that rely heavily on international suppliers?

Ara Ohanian: Potential changes to trade policies—including tariffs and import regulations—could significantly impact SMBs with international suppliers. If tariffs increase, costs for SMBs, especially those dependent on imported goods, could rise. These additional costs might be passed on to customers, impacting competitiveness in an already price-sensitive market. On the other hand, certain policy shifts could encourage investments in domestic manufacturing, opening new opportunities for businesses to source materials locally. This shift could reduce lead times and increase supply chain stability.

SC247: What are some of the biggest challenges SMBs face when trying to diversify their supply chains, and how can they best approach nearshoring or exploring new suppliers?

AO: American SMBs are increasingly bringing their supply chains closer to home. According to Netstock research, only 25% of U.S. respondents prefer offshore suppliers over domestic ones. However, challenges remain. Raw materials often still need to be sourced internationally, meaning locally-held inventories may need to grow temporarily to offset supply chain variability. Additionally, SMBs lack the capital of larger enterprises, making it harder to afford the upfront costs of shifting suppliers or relocating supply chains.

To effectively approach nearshoring, SMBs can gradually diversify their suppliers to mitigate risk and establish partnerships with flexible payment terms. Implementing inventory management tools unlocks real-time data and visibility, enabling optimized stock levels, accurate inventory forecasting, and improved supplier communication. These tools help SMBs reduce inventory holdings and free up cash tied to excess stock.

SC247: What role does strategic stockpiling play in helping SMBs manage tariff risks, and what are the negatives of this approach?

AO: While excess stock can lead to hidden costs and risks, Netstock views it as an “unexpected opportunity,” especially for inventory redistribution. By redistributing surplus stock to areas of demand, SMBs can optimize resources without incurring additional costs. This ensures supply chains meet demand and avoid lost sales using already available stock.

The key to successful stockpiling is inventory visibility. Adopting inventory management tools allows SMBs to spot surplus stock in real-time. With greater visibility, businesses can make strategic stock purchases to prepare for potential tariff increases while minimizing costs and risks.

SC247: Given Netstock’s experience managing inventory for SMBs, what strategies would you recommend for companies to build a more resilient supply chain?

AO: 1. Diversify suppliers: Relying on a single supplier or region, especially those outside North America, creates vulnerabilities to trade disruptions. SMBs should establish multiple supplier relationships and explore nearshoring to build redundancy and flexibility in sourcing.

2. Leverage predictive technology: Predictive analytics and inventory management tools enable scenario planning, optimized inventory levels, and proactive risk mitigation. According to Netstock research, nearly 80% of SMBs struggle with insufficient planning and overstocking. With predictive tools, SMBs can act ahead of challenges.

3. Maximize inventory opportunities: Advanced AI can analyze inventory data across all locations in real-time, providing actionable insights to prevent stockouts and improve inventory management.

4. Foster collaboration: Open communication channels with key partners, suppliers, and logistics providers help businesses identify challenges early and collaboratively develop strategies to address them.

SC247: Are there specific sectors or product categories that you believe will be most affected by potential new tariffs?

AO: Industries like consumer goods, automotive, and manufacturing could be heavily impacted. Consumer goods sectors, such as apparel, electronics, and personal care, rely significantly on imports from China and may face higher costs. Tariffs on critical materials like steel, aluminum, and semiconductors could increase prices in the automotive and manufacturing sectors. Manufacturing, in particular, faces the added complexity of forecasting not only supply and demand for finished goods but also the components needed for future production processes.