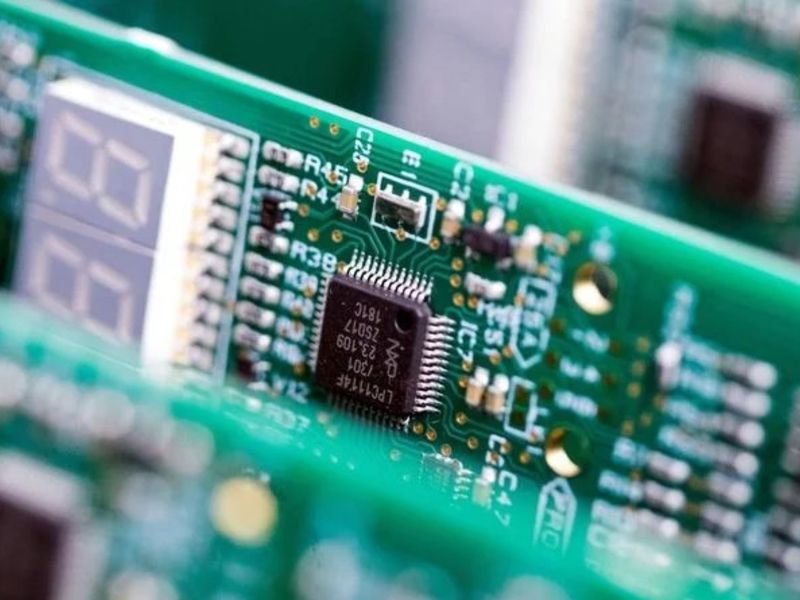

DETROIT — The latest signs the global semiconductor shortage may be easing? Ten cents and the Chevy Malibu.

General Motors and Ford Motor Co. reported lower third-quarter earnings than a year earlier because of the parts crisis that has kept many dealer lots bare for months, but each automaker appears to be in better position to weather the shortage, which could linger through most of next year and into 2023.

Ford, predicting increased volume in the final months of 2021, raised its full-year guidance and said it would pay shareholders a 10-cent quarterly dividend for the first time since the coronavirus pandemic began. GM this week plans to resume production of the Malibu for the first time since early February, an indication that its chip supplies are stable enough to build even its lowest-priority vehicles. And Stellantis reported 14 percent lower revenue but reaffirmed its full-year profit margin guidance while predicting a “moderate” improvement on chip supply through the remainder of the year.

“It looks like things hit rock bottom in late September and early October,” Michelle Krebs, executive analyst at Autotrader, told Automotive News. “Sales won’t be robust by any stretch, but we’re seeing them pick up. There are a lot of reasons to be optimistic the market will improve.”

Still, chip constraints kept third- quarter earnings from surpassing year-earlier levels. Ford’s net income fell 24 percent to $1.8 billion, while GM’s dropped 40 percent to $2.4 billion.

“We’re doing everything we can to get our hands on as many chips as we can,” Ford CFO John Lawler said on an investor call. “We do see [the shortage] running through 2022. It could extend into 2023, although we do anticipate the scope and severity of that to reduce.”

Aside from an improving chip supply, Ford executives say the company’s revised guidance and dividend reinstatement — which will cost the company $400 million a quarter — stem from strength in the underlying business that it is unlocking with changes implemented by CEO Jim Farley.

The company is beginning to reap the rewards of a revamped product portfolio with the Bronco, Bronco Sport, Mustang Mach-E and Maverick driving up demand. With little inventory to spare, Ford has turned to a build-to-order system and has more than 130,000 orders banked. In the third quarter, the order bank represented 28 percent of Ford’s retail sales.

Farley says the company will keep the build-to-order model even after the chip crisis ends, noting that it helps Ford lower costs, reduce complexity and smooth future vehicle launches by providing a better sense of what configurations customers actually want. He has said Ford will operate with much lower inventory than it has traditionally.

Beyond those product changes, Ford is implementing a growth plan called Ford+ that centers on electrification, commercial vehicles and software services driving recurring revenue.

“We’re taking big swings,” Farley said on Ford’s earnings call.

Wall Street approves. After the company’s earnings announcement, Ford shares, which roughly doubled in Farley’s first year as CEO, reached their highest level since 2014, and Morgan Stanley analyst Adam Jonas called 2021 a “breakthrough year” for the automaker.

“Ford is convincing the stock market that they have a viable future,” Jonas wrote in a report to clients last week. “While they may have had a late start in some areas, they are beginning to appear like a successful fast follower.”

GM CEO Mary Barra said the company now expects 2021 adjusted earnings to come in at “the high end” of its $11.5 billion to $13.5 billion projection.

Barra said the high pricing created by the shortage of available inventory is largely responsible for that, along with its ability to keep full-size pickup and SUV production going while other plants have had lengthy downtime.

“We just can’t build enough of those vehicles,” she told reporters on a conference call.

GM had no downtime tied to the chip shortage scheduled in North America this week, the first time it had been able to resume full production since February. The company said it used just 60 percent of its two-shift production capacity in the third quarter, vs. 112 percent a year earlier, and its U.S. sales fell to the lowest level since the 2009 recession as dealership lots emptied.

Once inventories improve, GM “absolutely” expects to recoup the market share it has lost, Barra said.

“I am confident with the product line that we have and the new products coming that we will regain that as soon as we have more availability,” she said. “That definitely will be a priority.”

Stellantis did not report its full results for the quarter, but the company reaffirmed its guidance and said it’s on track to achieve a targeted 10 percent operating margin for the full year.

While North American dealer inventory dropped by 272,000 vehicles from the end of December, CFO Richard Palmer said demand for new products was strong.

That includes the Jeep Grand Cherokee L, Wagoneer and Grand Wagoneer SUVs and the upcoming next-generation Grand Cherokee.

The Wagoneer and Grand Wagoneer are “in one of the highest segments in terms of profitability in the U.S. market,” Palmer said. “We didn’t have anything there before.”

With those vehicles in the lineup, “I think North America as a business is in a good place,” he said.

But that’s the case only so long as the company has enough chips to keep the factories rolling. Stellantis lost 30 percent of its planned production — about 600,000 vehicles — during the third quarter. For the full year, the company expects to lose more than the 1.4 million units of production it previously forecasted, he said.

“What’s very healthy is that we’re turning vehicles very quickly,” Palmer said.

Nick Bunkley and Vince Bond Jr. contributed to this report.